C1.3 Mechanical Properties of Materials

In this subtopic, we will be looking at a few very important material properties that will be used throughout Solid Mechanics. But first, a quick recap on the stress-strain diagram.

Stress-strain (σ-ε) diagram

- σy is the yield stress, σUTS is the ultimate tensile stress.

- Material strains linearly until σy, and behaves elastically (i.e. it will return to its original shape when load is removed).

- After σy, non-linear strain occurs and the deformation is plastic (i.e. deformation is permanent and it will not return to original shape).

- After reaching σUTS, failure begins & necking ensues, and finally the material fractures and breaks into 2.

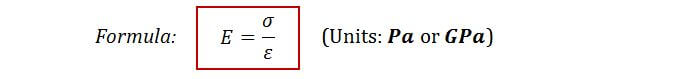

- The gradient of the elastic region is what we call the Young’s modulus.

C1.3 Mechanical Properties of Materials

In this subtopic, we will be looking at a few very important material properties that will be used throughout Solid Mechanics. But first, a quick recap on the stress-strain diagram.

Stress-strain (σ-ε) diagram

- σy is the yield stress, σUTS is the ultimate tensile stress.

- Material strains linearly until σy, and behaves elastically (i.e. it will return to its original shape when load is removed).

- After σy, non-linear strain occurs and the deformation is plastic (i.e. deformation is permanent and it will not return to original shape).

- After reaching σUTS, failure begins & necking ensues, and finally the material fractures and breaks into 2.

- The gradient of the elastic region is what we call the Young’s modulus.